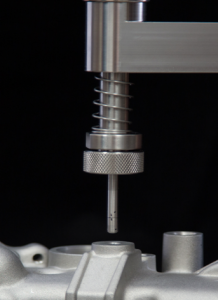

Example of high-speed thread inspection:

Customer Problem

A customer needed to inspect 100% of their valve covers for properly threaded holes. Because of the large number of threaded holes requiring inspection and the large size of the part, a dedicated multi-probe solution would have been very complicated and expensive. Using manual thread gauges for the test would be too time consuming. A vision system would also have been difficult and costly.

The customer wanted a system that would quickly identify partial and damaged threads, oversized and undersized threads, and an incorrect thread. In addition, the customer also needed to detect a missing hole or broken tap condition.

The Solution

Eddy current technology provided a fast, clean way to inspect threaded holes. For this solution the customer used a single eddy current probe assembly shown in Figure 1, combined with a high-speed robot. The fixture was spring-loaded to allow the probe to resist damage if the hole were missing or if a tap had broken off in the hole. Only one probe was needed to test all the top surface holes. The modular design of the probe assembly allowed for easy replacement of the eddy current probe in case it was damaged during production testing.

The complete test system consisted of the InSite HT test instrument, the spring loaded eddy current thread probe and an Epson robot. With this set-up, the robot was able to inspect one hole in much less than one second.

A video of the lab system proving the high-speed application action can be seen by clicking here.