Eddy current technology has been used to find flaws in bar, tube, and wire products for decades. The speed of response and repeatability of results make the inspection method perfect for high speed continuous flow production. Plus, materials do not have to be cleaned prior to inspection.

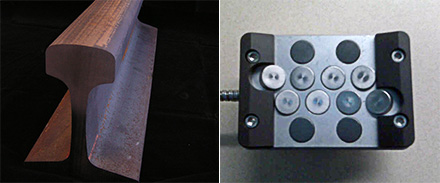

For finding medium to large flaws, a circular probe with multiple windings offers good results. If a flaw is discovered, our eddy current instrument sends commands to markers or cutters to highlight or remove defective product.

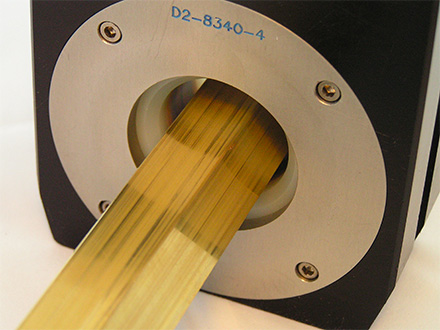

Fixturing is a critical factor to keep the material from wearing away the eddy current windings. Our probes can be made from a few thousandths to many inches in diameter.

For finding very small flaws, such as pin holes in aluminum tubing, we use multiple coil flaw probes in specially designed fixturing. Our multi-channel eddy current instruments connect to multiple probes with overlapping coverage.

Other continuous flow testing applications include:

- Hydraulic tubing

- Medical tubing

- Air conditioning tubing