Criterion NDT Sorting Unit – CSU

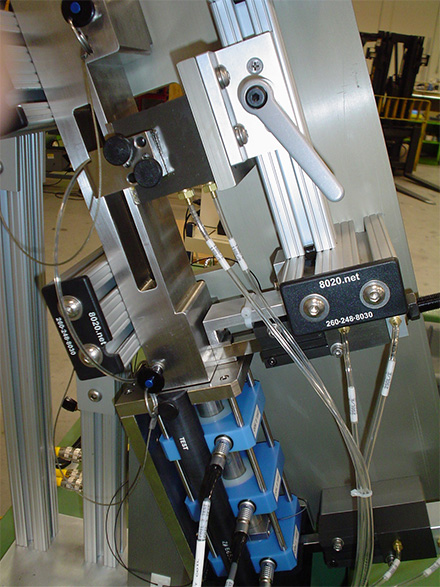

Criterion NDT’s new CSU material handling system/sorting unit provides manufacturers the ability to remove defective components from either in-line or off-line production processes by utilizing eddy current test results. Sorting parts by heat treatment conditions, alloy selection or assembly criteria saves time and unnecessary downstream processes resulting in cost savings. The CSU works with all Criterion NDT products.

The sorter is scalable to accommodate many product types and sizes, at rates of one or more parts per second. Bolt-on feeding guides and directional output chutes are easily attached.

Simple sorting stations can also be hand fed off-line and use gravity feed into single or multiple coils.

Download the Material Sorting Unit – CSU data sheet

Custom Material Handling Solutions

Criterion NDT works with material handling companies around the world to properly integrate eddy current systems into production lines. All of our test instruments are designed with industrial I/O that communicate to interface with PLCs used to control production lines.

Successful material handling systems must ensure that:

- The eddy current sensor (coil or probe) is in close proximity to the part under test, and the positioning is repeatable in order to maximize test results and minimize false rejects.

- For heat treatment verification (structure) testing, encircling coils are most often used. A coil can either surround the exterior of the part or be inserted within the part to access the critical test area.

- For a proper crack and flaw test, the probe is swept over the area to be tested. In most cases, the part is rotated or moved relative to the sensor. For the vast majority of crack inspection applications, it is critical that either the sensor or the part is moving relative to one another.

See our material handling videos.

Please contact us to learn more about our material handling solutions.